The Importance of Taking Care of Your Equipment

Posted by Andrew Greess on Dec 1, 2021

You’ve done everything right. You bought the best vehicle, wrapped it with your new logo, hired and trained the best techs, bought the best equipment and chemicals, hired skilled sales people to find great customers. But then, when the tech gets to the customer’s location, nothing. The equipment fails. This is frustrating, embarrassing and expensive and it has happened to all of us.

It is impossible to prevent all equipment issues but there are actions you can take to significantly reduce the likelihood of problems.

Here is a list of key considerations for Taking Care of Your Equipment

NOTE: We are excluding vehicles from list.

1. Clean It Out

Any piece of termite control or pest control equipment that is used to apply a product, regardless of form (liquid, dust,

granule, etc.) or application methodology (spray, dust, mist, fog, etc.) needs to be cleaned out.

Dirty or clogged equipment is one of the most common problems we see in our equipment repair shop. We are continually surprised by the number of customers who pay us to clean out their equipment. Keeping equipment clean is the responsibility of the technician using that equipment.

In addition to causing downtime, chemical buildup in application equipment can cause damage to the equipment and can affect application effectiveness. An example of this latter situation is chemical build up on the bottom of a spray tank. Chemical built up inside a tank is not protecting the customer and the customer is not getting the value she paid for.

It is particularly important to make sure the filter is clean on your hand sprayers, backpack sprayers and power sprayers. Clogged filters are without question the leading cause of equipment problems. This is surprising because it is just about the easiest thing to check and correct.

2. Release the Pressure

Lots of pest control equipment uses pressure to apply product (sprayers, dusters, misters, foggers, etc.). Another great way to reduce spray equipment problems is to release the pressure. Release the pressure on your (power or manual) sprayer after each stop to prevent problems. Release the pressure by squeezing the spray gun handle to let the pressure drop in the line. The power sprayer must be turned off and the manual sprayer should not be pumped up. If spraying extra chemical on the ground is a problem, open the lid of the sprayer tank and spray the product back into the tank.

- Releasing the pressure on the sprayer extends the life of soft parts like hose, o-rings, gaskets, etc. We used to suggest releasing the pressure at the end of the day, but technicians forget and sprayers end up stored under pressure all night. Remember summer temperatures on the truck are higher than ambient, so the pressure in your system will increase if you don’t release the pressure.

- Releasing the pressure also reduces the chance of freeze damage should a deep freeze occur. If the sprayer is stored under pressure and the temperature drops, there is nowhere for the water to expand. The weakest link in the system will break when the water freezes.

- Train technicians to release pressure of all power and manual compressed air sprayers at the end of each stop to extend the life of your equipment and reduce breakdowns and downtime

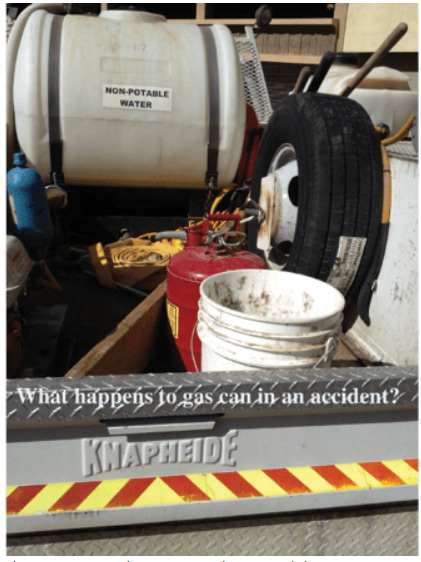

3. Secure That Load

We see three risks from unsecured equipment in your vehicle.

- Equipment bounces or rolls around truck and becomes damaged.

- Our repair shop sees this often. Mostly it is backpacks and 1-gallon hand sprayers that are damaged. This is totally avoidable.

- Loose equipment damages other equipment, for example a spray pump or tank.

- Loose equipment flies out of the truck in a crash or other emergency. This is really scary and could result in an expensive lawsuit.

A couple of key points

- Just because equipment is in the truck don’t assume it is secure

- Just because equipment is secure under normal driving conditions, don’t assume it will be secure in emergency conditions

- Check your equipment/load before driving off

4. Prevent Freeze Damage

Surprise! It gets cold in the winter and stuff freezes! It happens every year. Every year our shop has a run on pump bodies, spray wands and guns, filters, etc. All the stuff that breaks when water freezes in a sprayer.

This was the subject of a previous PCT article: https://www.pctonline.com/article/wild-winter/

Here are some key points from that article:

- If possible, do not expose equipment to freezing temperatures. Move it inside and keep it warm.

- Drain water from equipment if possible

- Remember; never store the system under pressure. Equipment that is left under pressure in freezing temperatures is much more likely to burst or experience other damage.

- Remove the high-risk components: pumps, filters, spray wands and guns.

- If you can’t do any of the above, protect equipment with: insulation or blankets, heated blankets, heat cables, electric lights (not fluorescent).

- Put some anti-freeze in the tank and run the system just long enough to get the anti-freeze into the pump and other key areas

- Never start or run frozen equipment. Let it thaw out before starting.

5. Equipment Inspections – Trust but Verify

I am continually amazed at the number of avoidable pest control equipment repairs we see each week in our shop. These repairs cost companies money that could be better spent.

If you don’t periodically check on your technicians, you may be getting unintended results that impact your customers and cost you money.

Owners, managers or supervisors should perform periodic truck inspections. Start with regular, frequent inspections and reduce frequency as the results of the inspections improve. Truck inspections can be scheduled or on a surprise basis.

One of our customers does a truck inspection bi-weekly before a technician can collect his or her paycheck. Another client has a supervisor perform the inspections while the techs are inside for the monthly training meeting.

Here is a brief checklist to get you started.

Cleanliness

- Chemical buildup on the tank or in truck bed?

- Debris/trash in bed?

- Is truck clean & sparkling to support your brand?

Leaks

- Any puddles in the truck?

- Is there liquid anywhere it is not supposed to be?

- Any water/chemical stains on equipment to indicate leaks?

Security

- Tank bands intact and properly securing tank?

- Toolboxes secure – no rust at securing bolts?

- Toolbox locks functioning properly?

- Hand tools secure? Can’t roll, bounce, fly out of truck

- All equipment securely attached to truck?

Safety

- Sharp or jagged edges creating a hazard?

- Hot (engine) components creating a burn hazard?

- Moving parts have guards to prevent injury?

- Hose reel lock functions properly?

Any obvious damage or excessive wear on equipment? For example: are spray wands being used as crowbars, is engine pull cord frazzled, etc.

You can create a customized inspection list for your company’s equipment, e.g., check: sprayer filters, sprayer wands, equipment stored under pressure, etc.

The above inspection should take no more than a few minutes per truck. The payback in reduced downtime, fewer missed appointments and lower pest control spray equipment repairs will be significant.

You will find coaching opportunities to provide feedback to technicians. You will also identify equipment problems at the office, where they are easier, faster and cheaper to fix than in the field.

Consider rewarding technicians that repeatedly keep their equipment in excellent condition.

6. Technician Training

Most companies do a good job training techs Day 1 on equipment use. But just because you trained Tommy Tech on Day 1, doesn’t mean he is still doing what you want him to do. People forget. They get rushed. They find shortcuts. They copy other techs’ bad habits.

Shortcuts often reduce equipment life and cost you money. Do periodic retraining on pest control equipment.

Technicians will live with problems. Many of the equipment problems we see in our repair shop are significantly worse than they need to be. In too many instances, spray techs have ignored problems in the hope that they will go away. Remember, “hope” is not a strategy.

Equipment problems do not get better and they do not go away. Much like the slow drip of your kitchen faucet, spray equipment problems ALWAYS get worse. Small problems inevitably become big problems. Big problems cost more and take longer to fix.

Encourage techs to report problems. When a tech reports a problem, don’t rip his head off. It will discourage him (and others) from reporting problems in the future.

7. Keep a backup

As Pest Professionals, we rely heavily on our equipment, yet in many cases we have no backup. If you have a piece of equipment that is critical to your business then it is vital that you have a backup.

It doesn’t matter what the equipment is, if you can’t do your job without it, keep a backup.

We see companies of all sizes, from owner/operator to huge nationals surprised when a key piece of equipment fails.

What happens when we don’t have the equipment we need to complete our jobs?

- Missed & cancelled appointments

- Unhappy customers

- Lost revenue

- Employee downtime waiting for equipment

- Employee downtime running around town trying to find a solution

- Overtime expenses

- Higher repair expenses.

What do we do about this problem?

1. Identify critical equipment.

Review your equipment by vehicle, by service, by technician to identify the most important tools.

2. Develop a backup plan for each critical item

For some items it may be easiest to buy a replacement. For more expensive items, you may have to get creative. Look through that pile of used equipment in the corner and see if you can create something valuable out of it. Replace a hand sprayer a few months earlier than required and reserve the used one as a spare. Keeping a trailer in reserve can be cheaper than keeping an extra vehicle in the fleet.

3. Review your plan.

Review your backup plan annually to ensure it is still applicable. Test the backup equipment periodically to ensure it is functioning properly. Don’t assume that equipment sitting in the corner for years is still going to work.

A little time spent identifying critical equipment and developing backup plans will save time, money and stress during your busy pest control season.

8. Preventative Maintenance

Your pest control equipment requires maintenance. It doesn’t matter how much you paid or how well you take care of it. Hard use, harsh chemicals, long hours all take their toll.

The question is when do you do the maintenance? There are only 2 possible answers to this question. You can decide when to do the maintenance or you can let the equipment decide.

If you decide, then you can perform maintenance when it is convenient for you and your business. Slow periods, vacations, etc.

If you let the equipment decide, then here is what happens. Your equipment will fail when it is least convenient for you. It will fail when you are busy. It will fail when your clients need you. It will fail when the repair shop is very busy, so the repairs will take longer.

Take control. Plan your maintenance.

In summary, many equipment problems are preventable. A little planning and some advance work will reduce downtime and expenses and result in happier customers and employees.